In today’s fast-paced business environment, efficient maintenance management is critical for ensuring that operations run smoothly and that downtime is minimized. While many organizations still rely on spreadsheets to manage maintenance activities, this approach has limitations that can hinder productivity and profitability. Computerized Maintenance Management Systems (CMMS) offer a superior alternative, providing automated tools for managing maintenance activities, improving communication, and increasing visibility into maintenance processes. In this article, we will explore the advantages of using a CMMS over spreadsheets for maintenance management and provide guidance on how to make the transition to a CMMS successfully.

Benefits Of Using CMMS Over Spreadsheets

Increased Efficiency: CMMS software can automate many of the manual tasks associated with maintenance management, such as scheduling work orders, tracking inventory, and generating reports. This can reduce the time and effort required to manage maintenance activities, freeing up time for more strategic tasks.

Improved Accuracy: Manual data entry and management with spreadsheets can be prone to errors, which can lead to costly mistakes and rework. CMMS software can help to reduce errors and improve accuracy by automating data entry and providing real-time updates on maintenance activities.

Better Communication: CMMS software can help to improve communication among maintenance teams by providing a centralized location for tracking and sharing information. This can help to ensure that everyone is on the same page and has access to the latest information about maintenance activities.

Increased Visibility: With a CMMS, maintenance managers can have greater visibility into maintenance activities, equipment performance, and inventory levels. This can help to identify trends and patterns that can be used to optimize maintenance processes and improve equipment reliability.

Improved Asset Management: CMMS software can help to track the lifecycle of equipment, from purchase to disposal, providing insights into maintenance costs and identifying opportunities to improve equipment performance and reliability.

Regulatory Compliance: Many industries are subject to strict regulations and compliance requirements. CMMS software can help to ensure that maintenance activities are compliant with these regulations, reducing the risk of penalties and fines.

Cost Savings: By automating maintenance processes, reducing errors, and improving equipment performance, a CMMS can help to reduce maintenance costs and extend the life of the equipment.

Better Predictive Maintenance: CMMS software can help to identify equipment issues before they become major problems by tracking equipment performance and providing alerts when maintenance is due. This can help to prevent downtime and extend equipment life.

Improved Record Keeping: With a CMMS, maintenance records can be stored and accessed electronically, making it easier to retrieve information about past maintenance activities and track equipment performance over time.

Mobile Accessibility: Many CMMS software systems offer mobile access, allowing maintenance teams to access work orders, inventory levels, and equipment information from their mobile devices. This can help to improve productivity and responsiveness by allowing technicians to work from anywhere.

Increased Accountability: With a CMMS, maintenance teams can be held accountable for their work, as all maintenance activities are tracked and recorded in the system. This can help to improve the quality of work and reduce the risk of errors or oversights.

Improved Decision Making: CMMS software can provide maintenance managers with the information they need to make informed decisions about maintenance processes, equipment replacement, and budgeting. This can help to optimize maintenance processes and ensure that resources are allocated effectively.

Better Customer Service: By improving equipment reliability and reducing downtime, a CMMS can help to improve customer satisfaction by ensuring that equipment is available when it’s needed.

Tips To Successfully Transition From Spreadsheets To CMMS

If you’re considering making the switch from spreadsheets to Computerized Maintenance Management System (CMMS software), it’s important to have a plan in place to ensure a smooth transition. While the benefits of a CMMS are numerous, making the change can be daunting. Here are some guidelines to help you make the transition to a CMMS successfully.

Define Your Goals: Before making the switch, define your goals for implementing a CMMS. What do you hope to achieve? Identify the specific benefits you want to gain, such as increased efficiency, better asset management, improved reporting, and reduced downtime.

Identify Your Needs: Determine the specific features and capabilities you need from a CMMS. Do you need mobile access? Integration with other systems? The ability to manage inventory? Understanding your needs will help you select the right CMMS for your organization.

Choose The Right System: Do your research to find a CMMS that meets your needs and budget. Evaluate multiple systems and compare features, user reviews, and pricing. Consider factors such as ease of use, scalability, and vendor support.

Develop A Plan: Once you’ve selected a CMMS, develop a plan for implementation. Assign roles and responsibilities, set a timeline, and identify any training needs. Communicate the plan to all stakeholders to ensure buy-in and support.

Migrate Your Data: If you’re transitioning from spreadsheets, you’ll need to migrate your data to the new system. Be sure to clean up your data and ensure it’s formatted correctly for the new system. Some CMMS systems offer data migration services to make the transition easier.

Train Your Team: Ensure that all team members who will use the CMMS receive proper training. Provide hands-on training and offer ongoing support to ensure the adoption and successful use of the new system.

Monitor Progress: After implementation, monitor progress and track key performance metrics to ensure that the CMMS is delivering the expected benefits. Make adjustments as necessary to optimize performance and achieve your goals.

Establish User Access Controls: Implement user access controls to limit access to sensitive information. Define user roles and permissions based on the specific tasks they perform and the level of access they require.

Regularly Back Up Your Data: Regularly back up your data to prevent data loss in the event of a security breach or system failure. Make sure your backups are stored securely and off-site.

Choose A Secure CMMS: Make sure that the CMMS vendor that you choose has robust security features, such as user access controls, data encryption, and regular security updates.

Final Thoughts

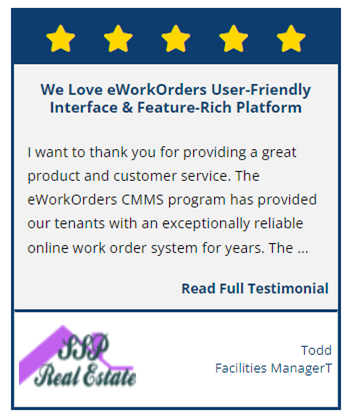

In conclusion, transitioning from spreadsheets to a CMMS can be a game-changer for your organization’s maintenance management strategy. By following the guidelines outlined in this article, a smooth and successful transition can be achieved. With the right CMMS in place, such as eWorkOrders CMMS, you can streamline your maintenance operations, improve asset management, and ultimately increase productivity and profitability. Remember to prioritize data security, regularly train your team, and consistently monitor progress to ensure the ongoing success of your CMMS implementation.