“The eWorkOrders platform has streamlined our operations and maintenance workflow, increasing productivity and efficiency. The responsiveness of the technical team and system features has improved communication, data integration, and KPI benchmarking.”

Running a wastewater treatment plant is no easy task—you’re under constant pressure to keep operations running smoothly while juggling equipment breakdowns, compliance requirements, and unplanned downtime. Every delay costs you time, money, and resources, and the stress of managing everything manually only makes it worse. That’s where eWorkOrders wastewater maintenance CMMS comes in. Designed specifically for plant operations like yours, we help you take control, reduce headaches, and keep your facility operating at peak efficiency.

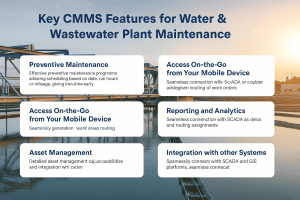

Key CMMS Features for Water & Wastewater Plant Maintenance

Key CMMS Features for Water & Wastewater Plant Maintenance

Preventive Maintenance

Effective preventive maintenance programs are essential to the success of your operation. Our software allows you to schedule preventive maintenance based on date, run hours, or mileage, giving you the power to craft the perfect maintenance schedule for each of your pieces of equipment. Using eWorkOrders CMMS software for treatment facilities offers an easy way to view and manage open work orders, upcoming preventive maintenance, and ongoing maintenance tasks to help facility managers stay updated and on track.Access On-the-Go from your Mobile Device

eWorkOrders’ powerful suite of features is accessible on any smartphone, tablet, or computer for the ultimate convenience. Scan an asset barcode to instantly pull up asset details, repair history, replacement parts, take a picture of the repair, and create the work order while you’re in the field and on the job. It is that quick and easy!Work Order Management

In a well-designed wastewater management system, work order management is seamless from start to finish. As issues are reported or routine maintenance comes due, the system automatically generates work orders. Each order includes clear job instructions, equipment history, required tools, and safety guidelines, so technicians show up prepared. From there, assignments are instantly routed to the right team members based on availability and skill set.Asset Management

There should be detailed asset management capabilities to ensure that every component, from pumps and motors to filters and valves, is accurately recorded and monitored. By organizing assets into clear hierarchies based on location, system, or function, teams can quickly navigate to specific equipment and maintain operational clarity. Integration with condition monitoring tools and IoT sensors enables real-time insight into asset performance, allowing operators to anticipate issues before they escalate.Reporting and Analytics

The software should deliver clear, actionable reporting that supports informed decision-making. It should have built-in analytics tools to track asset performance over time, flagging issues early to reduce unexpected downtime, and help teams manage resources more effectively. By analyzing maintenance trends like work order completion rates and equipment reliability, the software gives operators a full view of what’s working and what’s not.Integration with other Systems

Integration with other systems is another essential feature of wastewater management software. It should seamlessly connect with SCADA and GIS platforms to enhance visibility across infrastructure and enable real-time monitoring and geographic insights of your facilities. The software should also be able to connect with sewer system management tools to monitor sewer line conditions, track maintenance histories, and coordinate stormwater and combined system responses. CMMS tools play a vital role in managing unexpected events like those covered in our emergency maintenance article.Benefits of a Water Waste Management Software

Discover some of the benefits of a reliable water waste management software for efficient plant operations.Reduce Unplanned Downtime with Proactive, Predictive Maintenance

Unplanned downtime can derail even the most efficient wastewater operations. By shifting from reactive fixes to predictive maintenance, your maintenance team gains control over asset performance. Wastewater software equipped with real-time data, mobile access, and automated alerts enables proactive maintenance activities. Integrated sensors provide constant updates on critical tasks, helping reduce maintenance costs and extending asset life.Meet Regulatory Requirements and Stay Compliant with Confidence

From drinking water standards to wastewater treatment guidelines, the right platform simplifies compliance, supports informed decision making, and protects water quality. eWorkOrders CMMS asset management software with mobile computing makes it much easier to avoid hassles and stay compliant. Water and wastewater utilities can leverage our asset management software to keep a constant check on their vital equipment and to configure customized reports for audits or year-end reporting.Extend the Service Life of Aging Assets

Our wastewater management CMMS enables teams to detect and address minor issues before they escalate into costly failures, reducing wear and tear on critical components such as pumps, valves, pipes, and treatment equipment. This proactive approach not only ensures compliance with maintenance protocols but also leads to a decrease in MTTR (Mean Time to Repair) and improved asset reliability. Aging assets remain in peak working condition longer, minimizing unplanned downtime and extending their operational lifespan. As a result, organizations avoid expensive replacements and maximize the value of their existing infrastructure while maintaining high levels of reliability and efficiency.Optimize Costs

By providing real-time monitoring, predictive maintenance, and automated processes, you gain full control over system performance while lowering maintenance costs and energy usage. Since the software helps ensure regulatory compliance, it reduces errors and minimizes the risk of costly penalties. Also, with accurate field data, integrated sensors, and real-time updates, your maintenance team can stay ahead of critical issues and avoid expensive setbacks. This will lead to smarter, more informed decision-making and more efficient wastewater operations.eWorkOrders CMMS Water and Wastewater Software Solution

- Simple to use. Intuitive design makes navigation effortless.

- Quick setup. Get started in minutes with your free trial!

- Powerful platform. Packed with robust tools and advanced capabilities.

- Cost-effective. Flexible pricing to fit every organization’s budget.

- Exceptional support. Knowledgeable team ready to help anytime.

- Fully adaptable. Tailored options to meet your exact needs.

Frequently Asked Questions

How can maintenance management software improve wastewater operations?

Maintenance management software streamlines scheduling, tracking, and reporting, ensuring equipment reliability and regulatory compliance. It helps teams plan preventive maintenance, reduce unexpected breakdowns, optimize resources, and improve efficiency, ultimately saving time, lowering costs, and enhancing wastewater treatment performance.

What types of maintenance tasks can wastewater facilities manage with this software?

Wastewater facilities can manage preventive maintenance, inspections, work orders, asset tracking, and compliance documentation. The software organizes routine tasks, ensures timely repairs, improves accountability, and provides visibility into operations, making it easier to maintain equipment and meet regulatory requirements.

What makes a wastewater maintenance management system different from a general maintenance tool?

A wastewater maintenance system is designed for specialized industry needs, such as regulatory compliance, asset monitoring, and environmental reporting. Unlike general tools, it focuses on wastewater-specific workflows, safety protocols, and operational data, ensuring efficiency and reliability in treatment facilities.

How does predictive technology and AI help optimize wastewater treatment processes?

Predictive technology and AI analyze equipment data to detect issues early, forecast failures, and recommend maintenance actions. This minimizes downtime, extends asset lifespan, improves energy efficiency, and ensures wastewater treatment facilities operate safely, cost-effectively, and in full regulatory compliance.

Can wastewater maintenance software help reduce downtime and compliance risks?

Yes, the software automates preventive maintenance, ensures timely inspections, and keeps detailed records for regulatory audits. By tracking asset performance and anticipating issues, it reduces costly downtime, improves operational reliability, and helps facilities consistently meet environmental and compliance standards.